Call Us:

951-736-9386

Email: support@cmcconverting.com

9546 Commerce Center Dr. Rancho Cucamonga, CA 91730

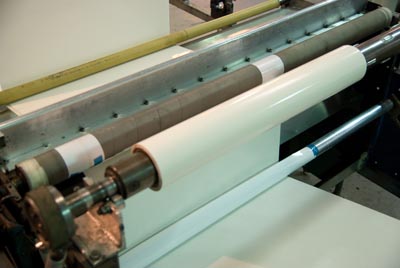

Slitting / Rewinding / Laminating

Services

VENDOR PARTNERS

Want to work with us?

Our goal is to provide you with effective solutions to meet your unique requirements.

Contact us today to get started!